Product Classification

Contact

Email: Grace@henanfoodmachinery.com

WhatsApp: +86-13938591459

Address: Building 30, Zhengzhou Equipment Manufacturing Industrial Park, No.1 Science and Technology Road 2, Xingyang, Zhengzhou, Henan, China

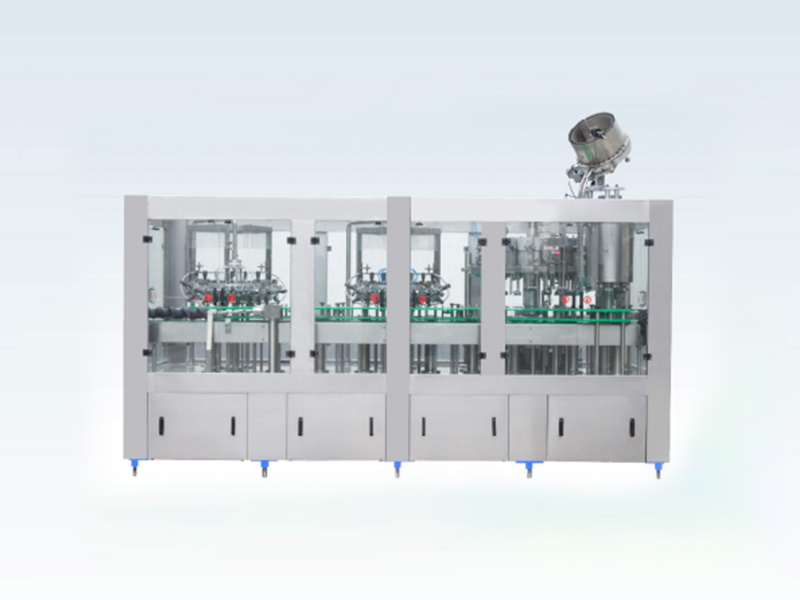

Bottled water three-in-one filling machine

This machine is mainly used for washing, filling, sealing, etc. of non-inflatable carbon dioxide beverages such as mineral water, pure water, and airless wine. This machine design shortens the time when beverage raw materials come into contact with the outside world and improves the overall economic benefits of sanitary conditions.

3-10L Linear Bottle Cleaning Filling and Capping Line

This production line is mainly used for liquid filling, integrating disinfection, rinsing, filling and sealing, with medium production capacity, simple structure and convenient operation.

Used for filling and sealing of various glass bottle caps in beer filling production lines.

MB-400 Heat Shrink Film Machine

This machine is specially developed for the combination packaging of mineral water, beverages, wine, beer, infusion medicine bottles and other products. It has stable functions and the packaging items are tight and orderly.

1、The body is made of stainless steel, aluminum alloy and square steel tube. 2、Welded pipe ensures smooth operation at high speed.

Automatic Sleeve Labeling Machine

This machine adopts international advanced technology to put round labels on PET bottles. Then it is heat-shrinkable and fixed in the designated position of the bottle. The machine has a compact structure and is suitable for production lines of different directions and heights.

Carbonated Drink Filling and Sealing Machine

This machine is a filling cover equipment designed based on the absorption of domestic and foreign technologies. It is mainly used for filling and cover of carbonated beverages such as soft drinks, cola, sparkling wine, etc., and has the advantages of structure, stable work, convenient operation and maintenance, frequency converter control, and high production efficiency. It is an ideal equipment for small and medium-sized beverage factories.