Exploring the Benefits of Advanced Filtration Purification Equipment: Enhancing Efficiency and Quality in Industrial Applications

Exploring the Benefits of Advanced Filtration Purification Equipment

Table of Contents

1. Introduction to Advanced Filtration Purification Equipment

2. Understanding Filtration Technology

2.1 Types of Filtration Systems

2.2 Key Components of Filtration Equipment

3. Benefits of Advanced Filtration Equipment

3.1 Improved Product Quality

3.2 Enhanced Operational Efficiency

3.3 Environmental Sustainability

4. Applications of Advanced Filtration Purification Equipment

4.1 Industrial Applications

4.2 Water Treatment and Purification

4.3 Pharmaceutical and Food Industry

5. Selecting the Right Filtration System for Your Needs

5.1 Assessing Your Filtration Requirements

5.2 Cost Considerations and ROI

6. Future Trends in Filtration Technology

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Advanced Filtration Purification Equipment

In today's industrial landscape, ensuring product purity and operational efficiency is paramount. Advanced filtration purification equipment is at the forefront of this effort, providing robust solutions to various filtration challenges across multiple sectors. This article explores the intricacies of these systems, showcasing their benefits, applications, and future potential.

2. Understanding Filtration Technology

Filtration technology has evolved dramatically over the years. Modern systems employ a plethora of techniques that enhance their efficiency and effectiveness in removing contaminants from liquids and gases.

2.1 Types of Filtration Systems

Different types of filtration systems are designed to meet specific needs. Here are some common types:

- **Microfiltration**: Effective in removing particles ranging from 0.1 to 10 microns, microfiltration is often used in water treatment processes.

- **Ultrafiltration**: A more advanced process, ultrafiltration can remove smaller particles, including bacteria and viruses, making it ideal for pharmaceutical applications.

- **Nanofiltration**: This technology targets even smaller molecules, allowing for selective separation of substances, beneficial in food and beverage industries.

- **Reverse Osmosis**: Known for its efficiency in desalination, reverse osmosis is vital in water purification, delivering high-quality water for various uses.

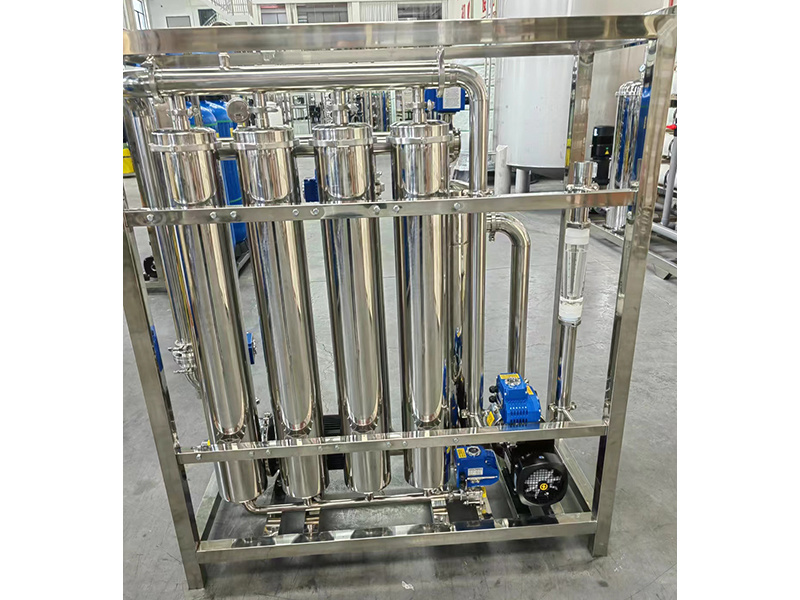

2.2 Key Components of Filtration Equipment

Understanding the components of filtration equipment is essential for optimal performance:

- **Filter Media**: The heart of any filtration system, filter media is responsible for capturing contaminants. Options include activated carbon, membrane filters, and synthetic materials.

- **Housing**: This component protects the filter media and ensures the system's integrity.

- **Flow Control Mechanisms**: Valves and pumps regulate the flow of liquids or gases, ensuring effective filtration.

- **Monitoring Systems**: Advanced filtration systems often incorporate sensors to monitor pressure and flow rates, maintaining optimal performance.

3. Benefits of Advanced Filtration Equipment

Investing in advanced filtration purification equipment brings numerous benefits to industrial operations:

3.1 Improved Product Quality

One of the most significant advantages of advanced filtration technology is the enhancement of product quality. By effectively removing impurities, manufacturers can ensure that their end products meet stringent quality standards, leading to increased customer satisfaction and loyalty.

3.2 Enhanced Operational Efficiency

Advanced filtration systems are designed to operate with maximum efficiency. They can handle larger volumes of material while maintaining consistent performance. This efficiency translates into reduced operational costs and increased productivity, allowing companies to allocate resources more effectively.

3.3 Environmental Sustainability

With growing environmental concerns, companies are increasingly focused on sustainability. Advanced filtration systems significantly minimize waste and energy consumption, contributing to sustainable industrial practices. By investing in these technologies, businesses can enhance their eco-friendly initiatives while complying with regulatory standards.

4. Applications of Advanced Filtration Purification Equipment

Advanced filtration systems are versatile and applicable in various industries:

4.1 Industrial Applications

In manufacturing, advanced filtration is vital for maintaining equipment and ensuring product purity. Industries such as automotive, aerospace, and electronics rely on these systems to filter lubricants, coolants, and other fluids, preventing contamination and extending equipment lifespan.

4.2 Water Treatment and Purification

Water scarcity is a pressing global issue, making effective water treatment essential. Advanced filtration technologies are employed in municipal water treatment plants, ensuring safe drinking water. Furthermore, these systems are crucial in industrial processes where water quality directly impacts productivity and product quality.

4.3 Pharmaceutical and Food Industry

In the pharmaceutical and food sectors, stringent hygiene standards are non-negotiable. Advanced filtration equipment ensures that products are free from contaminants, safeguarding public health. Technologies like ultrafiltration and nanofiltration are widely used to achieve the high purity levels required in these industries.

5. Selecting the Right Filtration System for Your Needs

Choosing the right filtration system is crucial for maximizing benefits and achieving desired outcomes.

5.1 Assessing Your Filtration Requirements

Evaluate your specific filtration needs by considering factors such as:

- **Type of Contaminants**: Identify what contaminants you need to remove from your process.

- **Volume of Material**: Determine the volume of liquid or gas that requires filtration.

- **Regulatory Compliance**: Ensure that the filtration equipment meets industry regulations and standards.

5.2 Cost Considerations and ROI

While investing in advanced filtration systems can require significant upfront costs, the long-term benefits often justify the expense. Consider the potential return on investment (ROI) by analyzing improvements in product quality, operational efficiency, and reduced waste.

6. Future Trends in Filtration Technology

The filtration industry continues to innovate, with emerging trends shaping the future:

- **Smart Filtration Systems**: Integration of IoT technology allows for real-time monitoring and automation of filtration processes, enhancing efficiency and reducing downtime.

- **Sustainable Materials**: The development of eco-friendly filter media and components is on the rise, aligning with global sustainability goals.

- **Membrane Technology Advancements**: Innovations in membrane technology are paving the way for more effective filtration solutions, particularly in water treatment and pharmaceutical applications.

7. Frequently Asked Questions (FAQs)

Q1: What industries benefit from advanced filtration purification equipment?

A1: Industries such as manufacturing, water treatment, pharmaceuticals, and food production all benefit from advanced filtration systems by ensuring product purity and operational efficiency.

Q2: How does advanced filtration improve product quality?

A2: By removing impurities and contaminants effectively, advanced filtration systems ensure that end products meet high-quality standards, leading to increased customer satisfaction.

Q3: What are the environmental benefits of advanced filtration systems?

A3: These systems reduce waste and energy consumption, contributing to sustainable industrial practices and helping companies comply with environmental regulations.

Q4: How do I determine the right filtration system for my application?

A4: Assess your specific needs by considering the type of contaminants, volume of material, and regulatory compliance requirements.

Q5: What are the future trends in filtration technology?

A5: Key trends include the development of smart filtration systems, sustainable materials, and advancements in membrane technology for more efficient filtration solutions.

8. Conclusion

In conclusion, the integration of advanced filtration purification equipment into industrial processes offers unparalleled benefits, from improved product quality to enhanced operational efficiency and environmental sustainability. As industries continue to face challenges related to contamination and resource management, investing in advanced filtration technology is not just a choice—it's a necessity. By understanding the various types of filtration systems and their applications, businesses can make informed decisions that lead to long-term success and competitiveness in the marketplace. Embracing these technologies paves the way for a cleaner, more efficient, and sustainable future.

Previous