Product Classification

Contact

Email: Grace@henanfoodmachinery.com

WhatsApp: +86-13938591459

Address: Building 30, Zhengzhou Equipment Manufacturing Industrial Park, No.1 Science and Technology Road 2, Xingyang, Zhengzhou, Henan, China

1、The body is made of stainless steel, aluminum alloy and square steel tube. 2、Welded pipe ensures smooth operation at high speed.

Automatic Sleeve Labeling Machine

This machine adopts international advanced technology to put round labels on PET bottles. Then it is heat-shrinkable and fixed in the designated position of the bottle. The machine has a compact structure and is suitable for production lines of different directions and heights.

Carbonated Drink Filling and Sealing Machine

This machine is a filling cover equipment designed based on the absorption of domestic and foreign technologies. It is mainly used for filling and cover of carbonated beverages such as soft drinks, cola, sparkling wine, etc., and has the advantages of structure, stable work, convenient operation and maintenance, frequency converter control, and high production efficiency. It is an ideal equipment for small and medium-sized beverage factories.

Metal can filling and sealing machine

This machine is suitable for isopressurized filling and sealing of beer and gas-containing beverages. Adopt the world's mechanical, electrical and pneumatic control technologies. It has the advantages of stable filling, fast speed, liquid level control, reliable sealing, frequency conversion speed regulation, small material loss, and EITC. We can install remote control systems according to customer requirements, which are the first choice and ideal equipment for medium-sized breweries and beverage factories.

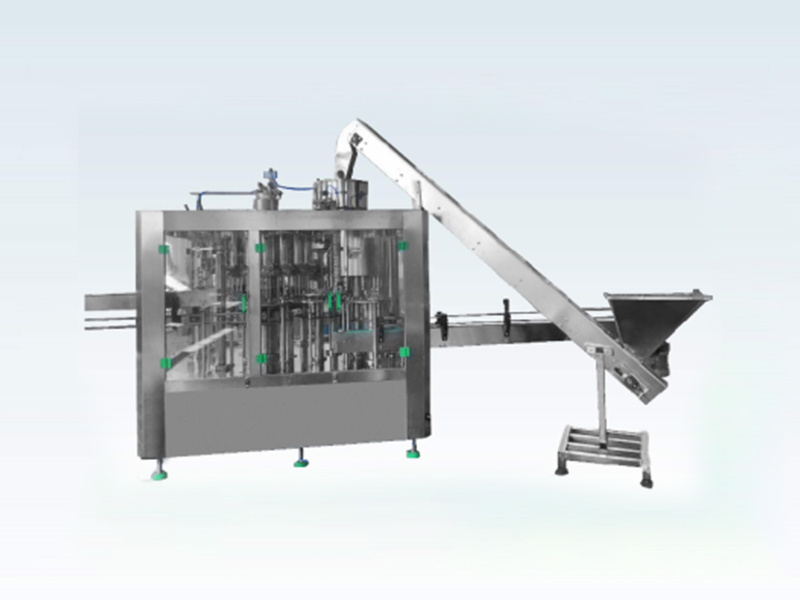

Automatic plunger filling machine

This machine is suitable for filling viscous, non-viscosity and corrosive liquids, and is widely used in vegetable oil, chemical liquids, daily chemical industries and other industries. It adopts linear filling and integrated control of electromechanical instruments, unique design, superior performance, and simple and quick replacement of varieties. The appearance conforms to international mechanical concepts.

Glass bottle red wine filling machine

The filling valve adopts a high-precision mechanical filling valve, which has the characteristics of no bottle or vacuum.

Granular Juice Filling Machine

Customers need to purchase additional conversion parts for different bottles. If using a square bottle, a bottle separation system will be added.

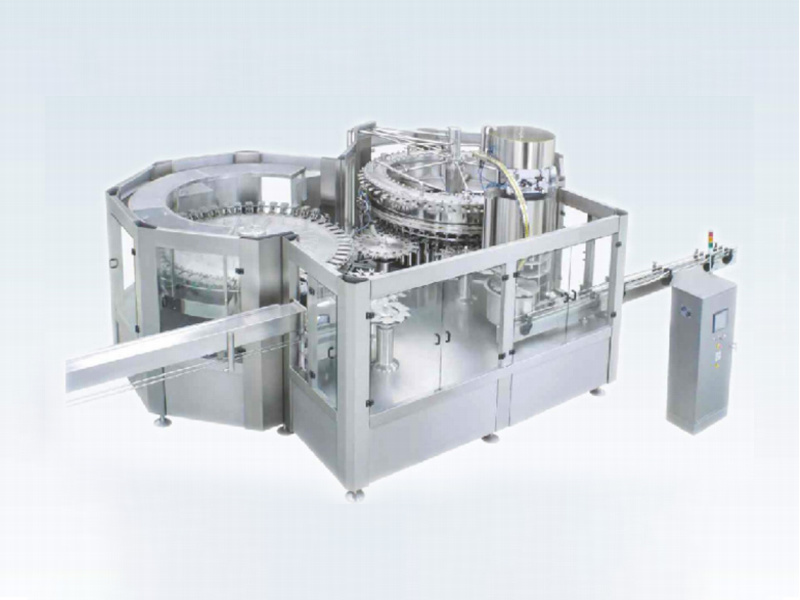

DCGF series carbonated beverage three-in-one filling machine

This series of equipment is suitable for the production of carbonated beverages with gas-containing polyester bottle packaging such as Coca-Cola, Pepsi, alcoholic beverages, etc.

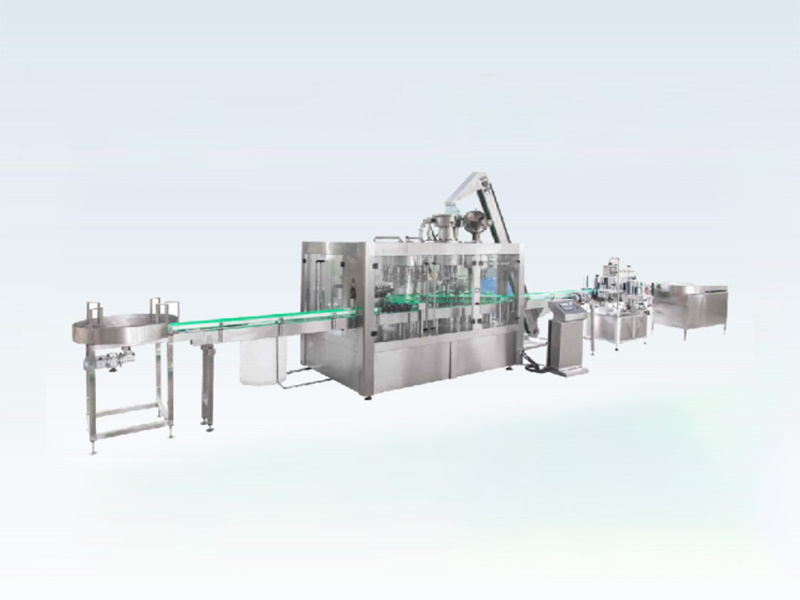

Split type atmospheric pressure filling equipment

The production line includes ZPC automatic cleaning machine, GFP automatic filling machine, YQX automatic capping machine, SSJ conveying, etc. The key components of cleaning, filling and capping are made of high-quality stainless steel, with the characteristics of complete process, complete system, reliable performance and convenient operation.